DIY Renovation Survival Guide: Staying Sane During Remodeling Projects

If you’ve ever done a DIY renovation, you know how stressful it can be. Instead of being overwhelmed on your … Continued

If you’ve ever done a DIY renovation, you know how stressful it can be. Instead of being overwhelmed on your … Continued

Do you have some old or antique furniture lying around the house? Don’t throw it out! Keep reading to learn … Continued

![My Biggest Chalk Paint Secret-Revealed [How to] 5 how to pant with chalk paint1](https://www.picklee.com/wp-content/uploads/2013/12/how-to-pant-with-chalk-paint1-231x300.jpg)

I’ve been working with chalk + clay paint for a many years now, and I think it’s safe to say that I … Continued

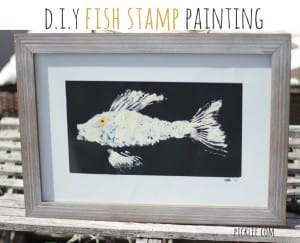

Living on the coast, I’m constantly inspired by unique beach art. Of course it’s mostly art I could never afford, … Continued

![Modern & Reindeer Printed Hand Towels [DIY] 10 reindeer painted handtowes](https://www.picklee.com/wp-content/uploads/2013/11/reindeer-painted-handtowes-300x245.jpg)

Who doesn’t love fun hand towels? I love to get festive with my kitchen towels this time of year, it’s nice way … Continued

![Funky Frosted Wine Glasses [DIY] 11 diy frosted wine glasss](https://www.picklee.com/wp-content/uploads/2013/05/diy-frosted-wine-glasss-240x300.jpg)

There’s nothing I love more than mixing up a nice refreshing skinny cocktail on a Saturday afternoon. The best part … Continued

![5 Mintute Spring Wreath [DIY Tutorial] 15 5 minute diy spring wreath](https://www.picklee.com/wp-content/uploads/2013/05/5-minute-diy-spring-wreath-266x300.jpg)

I was whirling around my house last weekend trying to tackle some much needed Spring cleaning when I opened up … Continued

![DIY Tooth Fairy Pillow-Wally Whale [tutorial] 17 tooth fairy pillow unique whale1](https://www.picklee.com/wp-content/uploads/2013/04/tooth-fairy-pillow-unique-whale1-300x200.jpg)

There are many fun traditions I miss from my childhood, waiting up at night for Santa to come, waking up … Continued